industrial automation

Automatically controlling complex production processes or efficiently operating production machines in a 24/7 production environment is exactly what makes our hearts beat faster.

read more contact uswhat is industrial automation?

Industrial automation uses technologies such as robots, AI and machine learning to make processes run smoothly and efficiently. Automated systems take over manual work, allowing tasks to be performed faster and more consistently. From sorting products to controlling robotic arms or real-time quality control – automation in industry makes it possible.

Industrial automation also enables the collection and analysis of large amounts of data. This provides a greater understanding of the performance of production processes and better informed decisions. In our rapidly changing world, understanding and implementing industrial automation is essential for companies that want to continue to innovate and compete.

technologies in industrial automation

When it comes to industrial automation, software solutions and technologies are key in enabling and streamlining these processes. Here are some of the key technologies at play:

Programmable Logic Controllers PLCs

PLCs are industrial computers specifically designed to control production processes such as assembly lines and robotic systems. They are robust, reliable, versatile and therefore the standard solution in numerous industrial automation systems. At SST we have extensive knowledge and experience with technologies from manufacturers such as Siemens and Beckhoff.

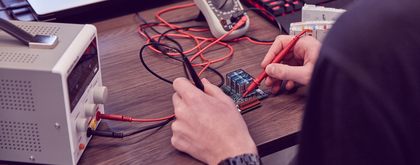

Printed Circuit Boards PCBs

These electronic components are the beating heart of any machine. They are designed to transmit electrical signals between different physical components within a device, such as sensors, microprocessors and memory modules. PCBs are essential for the operation of all electronic devices, from simple sensors to complex industrial robots. Our team of software engineers work closely with our team of hardware engineers at our sister company SST Hardware to ensure that our solutions integrate seamlessly with our customers’ hardware.

PCB design

With SST Hardware we have specialized in the design, development and production of various types of PCBs. From idea to end product. We have several experts in-house who are exclusively concerned with this.

Supervisory Control and Data Acquisition SCADA systems

These software solutions provide a central system to monitor processes in real time, collect and analyze data, and respond to changes in the process. They are indispensable for managing complex industrial automation systems on a large scale.

Industrial Internet of Things IIoT

IIoT is the connection between machines, computers and people to collect and share data about industrial processes. With IIoT devices you can gain real-time insight into the performance of machines. This makes it possible to plan proactive maintenance, increase efficiency and intervene quickly in the event of deviations.

Artificial Intelligence AI and Machine Learning ML

Machine Learning & AI are increasingly being used in industry to recognize patterns, optimize processes and even enable predictive maintenance. They can be used to analyze the vast amounts of data collected by IIoT devices and gain valuable insights.

Robotics

Software is the driving force behind programming and controlling robots in industrial environments. These robots perform dangerous, complex, precise or monotonous tasks, improving safety and efficiency. At SST Software, we integrate and optimize these technologies so that companies can get the most out of industrial automation.

The challenges of industrial automation

Industrial automation offers great benefits, but also brings challenges. A major challenge is keeping up with rapid technological developments. In order to offer the best solutions, we continuously stay up to date with the latest innovations. In addition, integrating our software with various hardware components is a great challenge, given the variation in technologies. With our broad knowledge and the support of SST Hardware, we successfully tackle this complexity.

Another challenge is to ensure user-friendliness, regardless of the user's technical level. We do this through close consultation with customers and extensive on-site testing. We also set high standards for reliability and security, because our software often plays a very important role in industrial processes. This is how we continue to guarantee quality and safety!

your unique solution from the ground up

If desired, we can develop a fully integrated solution "from scratch" together with you. Specifically for your unique production or business processes. We apply a high quality standard to all software development, industrial automation related or not.

Top-quality customization is our focus. This is often a better alternative, because standard software often just doesn't meet the requirements or is unnecessarily expensive. Our strength? Converting technical complexity into practical and simple solutions.

welcome solution

blogs about industrial automation

Why you should trash your old software (and how to rebuild it)

11 October 2023

“Why is this page so slow?” “Is there anyone who still can add our new products to this old software?” “Who broke my magical Excel ERP sheet?”

read more